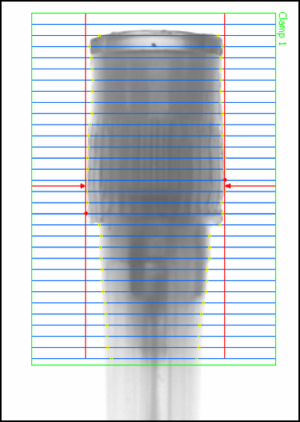

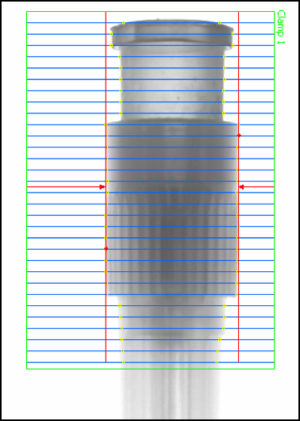

INDUSTRIES / Life Science / Syringe and IV Catheter Automation

Machine name: Syringe and capped needle assembly machine

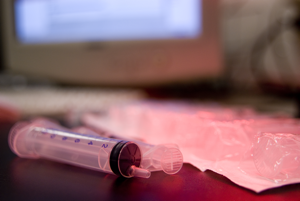

Product: three-part, disposable, Luer lock syringes with capped, hypodermic needle

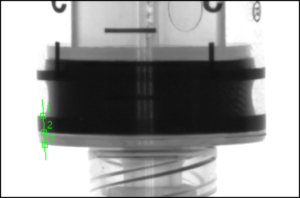

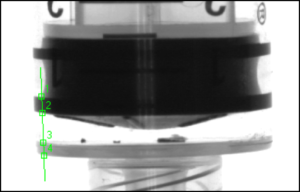

Function: fully automated, supply and assembly of hypodermic, capped needles with three different types of syringes. Before assembly, all parts are automatically inspected with our special made machine vision system based on LabView. Rejected parts are sorted out automatically. After assembly, completed parts are positioned in a blister for packaging.

|

|

|

|

|

|

Capacity: 240 products per minute; the machine assembles 1 mL, 2 mL and 5 mL syringes with capped needles. Increased autonomy with custom made linear feeders and bowl feeders. Short change-over times with no special tools. Easy-to-use machine set-up with pull-down menu on operator panel.

|

|

|

|

|

|

Extra: automated, integrated packaging blister unit

Improvement: efficiency improvement, quality improvement and  higher through putMachine name: Syringe and capped needle assembly machine

|

|

|

|

|

Product: three-part, disposable, Luer lock syringes with capped, hypodermic needle

Function: fully automated, supply and assembly of hypodermic, capped needles with three different types of syringes. Before assembly, all parts are automatically inspected with our special made machine vision system based on LabView. Rejected parts are sorted out automatically. After assembly, completed parts are positioned in a blister for packaging.

Capacity: 240 products per minute; the machine assembles 1 mL, 2 mL and 5 mL syringes with capped needles. Increased autonomy with custom made linear feeders and bowl feeders. Short change-over times with no special tools. Easy-to-use machine set-up with pull-down menu on operator panel.

Extra: automated, integrated packaging blister unit

For more information please contact our Sales

Call +31 45 543 9251 or e-mail sales@gdo-bv.com