INDUSTRIES / Energy / Ceramic Fuel Cell Cutting Machine

Fuel Cells are one of the new developments for alternative energy in vehicles. The Research Institute in Jülich (Germany) or Forschungszentrum Jülich is one of the leading institutes for alternative energy sources. After focussing on the nuclear industry for years on end, they now focus on for example these fuel cells.

|

|

|

|

Fuel cells come in different shapes and sizes. A fuel cell basically is a stack of ceramic plates, stacked up in a certain sequence. These ceramic plates are cut from a ceramic paste on a conveyer, comparable to a leather/fabric cutting machine. Because different case conditions apply such a cutting machine wasn’t applicable.

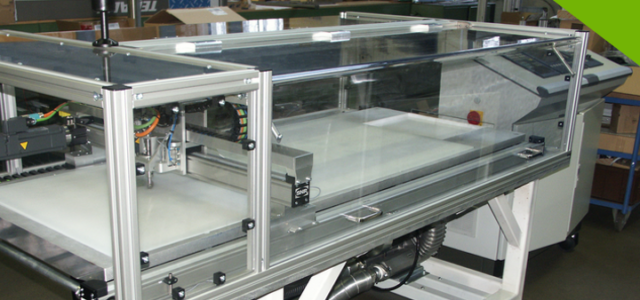

GDO developed cutting machine that is able to cut the different patterns, number them and stack them at the end of the cutting table. After that the operator can remove the stack of ceramic plates and put them in the oven for a heat treatment.

The challenge in this machine was not only the handling of the ceramic paste, but also the control of the plate. The blade not only moves in the X, Y and Z, but also has a rotational axis. For this control GDO used Siemens drives including a Siemens Numeric control system, similar to the ones used in milling machines. Not only for GDO, but also for Siemens a new and unique application.

Key words:

- - Cutting of ceramic paste

- - Special circular blade for clean cuts

- - Siemens servo drives

- - Siemens Numeric Control

- - Vacuum table to hold the ceramic paste

- - Shielding of critical processes

- - Clean environment within the shielding

- - Exhaust of particles

For more information please contact our Sales

Call +31 45 543 9251 or e-mail sales@gdo-bv.com