INDUSTRIES / Automotive / Porsche Wishbone Assembly

"Complex shapes"

The wishbone of a Porsche Panamera is all about finding the optimal relation between comfort and performance, which expresses itself as a complex 3D aluminium cast part with large bearings. Both these bearings and the cast aluminium part bring that combination of comfort and performance in terms of rigidness and flexibility.

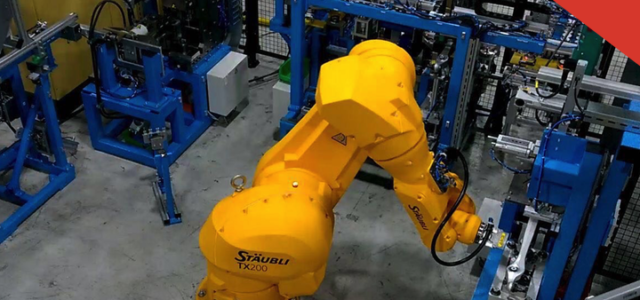

This machine uses the flexibility of a central 6-axis Robot from Stäubli to transport this complex 3D part from station to station.

Parts are placed on a conveyer:

At least 4 types of wishbones, namely standard left and right, and “R-type” left and right.

The robot transports the products to the following stations:

- Module 1: axial play measurement and label application

- Module 2: torsional moment and safety label application

- Module 3: assembly of bearing one (radial)

- Module 4: assembly of 3-component bearing (radial and axial)

- Module 5: assembly of hydro-bearing

After the assembly parts are either placed on an accepted or rejected conveyer; placement on the rejected conveyer means rework considering the high component value.

Key words:

- - All data gathered in a central computer

- - Integrated label application with serial number

- - Integrated safety label application

- - 6-axis robot from Stäubli (other makes possible as well)

- - 100% axial play test

- - 100% torsional moment test

- - Force and way controlled Presses

- - Torque and revolution controlled tighteners

- - 90 seconds cycle time

For more information please contact our Sales department

Call +31 45 543 9251 or e-mail sales@gdo-bv.com