INDUSTRIES / Automotive / Oil and water pump Test Equipment

I think everybody can guess what happens if one of the pumps in your car stops functioning. Overheating the engine, the transmission or even worse a runner up due to lack of lubrication. Imagine this happening when leaving for your holidays.

That is why GDO developed a series of test machines that are capable of testing your oil and water pumps, for engines and transmissions, for development testing or End-of-Line testing, manual or fully automated.

- - Endurance test machine

- - Operation check

- - Development test machine

- - End-off-line test machine

|

||

All systems are based on Labview or Adwin hardware and software. Development test machines have a much more advanced hardware with extreme sampling rates for highest generation of measurement data.

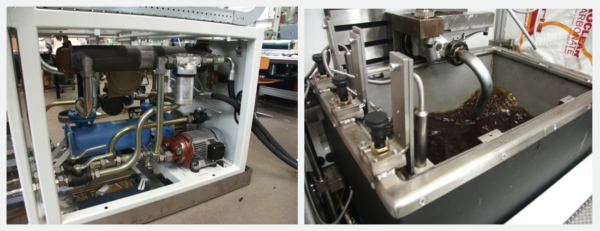

An example of a fully automated test machine is shown in the image below. This specific machine tests a transmission pump for a certain type of VW. The test machine is directly connected to the assembly machine next door (semi-cleanroom) where the pumps are placed in a “dry” buffer conveyer. The robot of the test machine takes one of the pumps from the buffer and places it in one of the four test rigs. After testing the pump is marked, laser coded and placed in a wet buffer.

Key words:

- - Particle measurement in Oil

- - Controlled by PLC

- - Test measurement and analysis by Adwin

- - Laser engraving with integrated DMC check

- - “Dry” and “Wet” buffer zones

- - “Dry and “Wet” gripper

- - Servo Robot for pick and place

- - Double oil circuit, one control circuit and one test circuit

- - Pressure, Flow and Torque measurement

- - Cleaning cycle after testing

- - 4 test stations

- - 60 seconds test cycle time

- - 15 seconds machine cycle time

For more information please contact our Sales

Call +31 45 543 9251 or e-mail sales@gdo-bv.com