Ultra High Speed Inspection

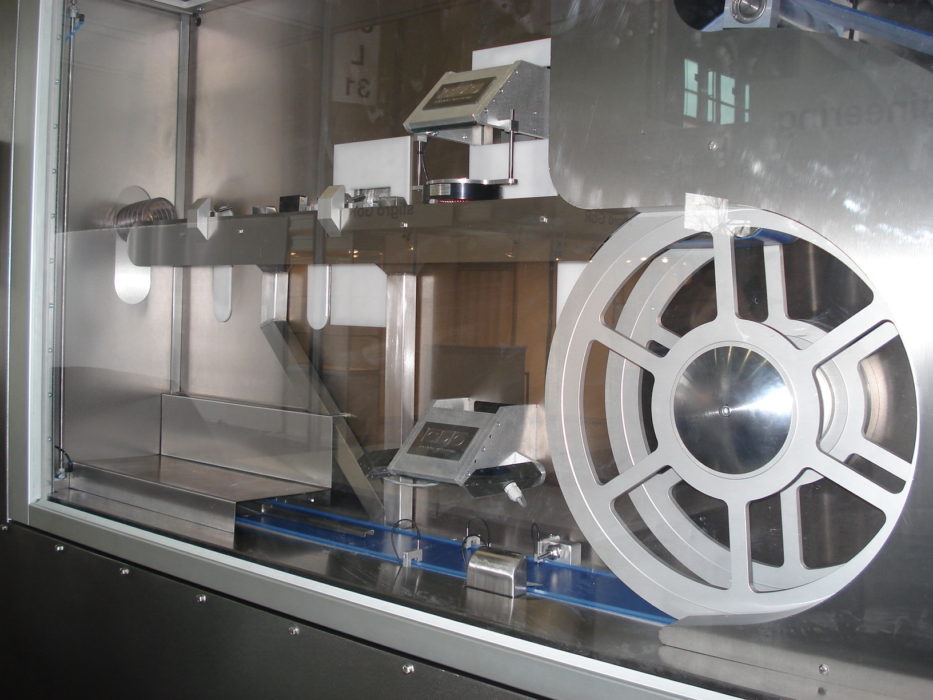

AISAP

An abbreviation for an inspection machine that is capable of inspecting any kind of product that fits in a 100x100x70mm box. Not only that, depending on the size of the product, inspection speeds of up to 50 parts per second can be reached! Incredible!

Why this kind of inspection machine you would ask. Well, we have been looking at the market of bulk inspection and found out that most of the machines have certain limitations and create certain risks:

- 1. Limited in terms of product types

- 2. After inspection, products are handled again

- 3. Limited speed

- 4. Limited to only one industry

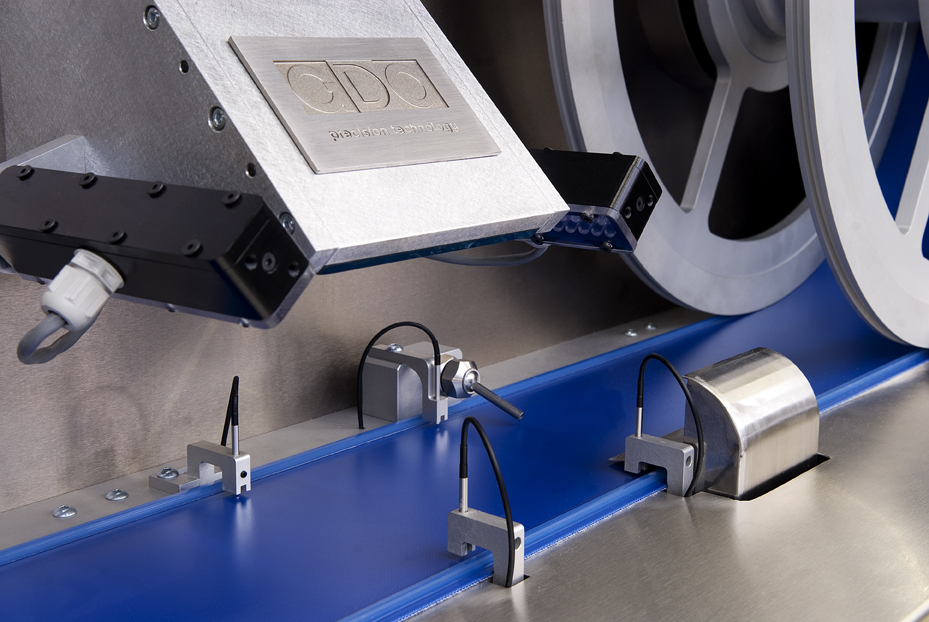

GDO took the limitations into account and went searching for a solution that could set the limitations aside. The AISAP.

We have chosen to cover all our industries: automotive, LifeScience, Packaging, Food and Energy. The variety of products is enormous. Think of rubber seals, plastic or Teflon seals, pills, candy, chocolate, chewing gum, metal washers, etc., etc.

The biggest innovation is the handling of parts. All our competitors actively grab the products after inspection and after that, don’t inspect them anymore. You get it.. risk rejected parts between the accepted parts.

GDO decided to develop a process that inspects the products on the top side, then flips the products without grabbing them, before inspecting the bottom side and the side. This makes sure that products aren’t damaged after inspection and makes sure that there are no rejected parts between the accepted parts.

As mentioned before, three inspections are executed:

- 1. Top side

- 2. Bottom side

- 3. Side

The cameras for these inspection are mounted on the backside of the system and are adjustable for optimal images. The lighting is directly above the product to make sure that as much light as possible is reflected to the cameras.

After evaluation, which is done in milliseconds, the rejected parts are immediately ejected by air nozzles with high-speed valves. Larger items are rejected actively by small sized cylinders.

For more information:

Please contact Stefan Lange our Sales Manager

E-mail stefan.lange@gdo-bv.com or call +31 45 546 4770 and ask for Stefan Lange.